Pioneering: The biodegradable plate material for signs

This is BioPanel:

- a biodegradable sheet material

- made of hemp fibers and biopolymers

- recyclable and/or completely compostable

- suitable for outdoor use

- CO₂ neutral

- stable and resistant

That is GreenFilm 100 PP LUVESS MW ultra tack air adh FR:

- a printable self-adhesive film

- PVC free

- self-adhesive with high adhesion

- Suitable for outdoor use in conjunction with Protect 70 PP matt;

Shelf life up to 5 years - with fire protection certificate

- printable with latex, UV-curing, eco solvent and solvent inks

In the interview

The innovative company BioPanel has developed a 100 % plant-based and recyclable (sheet) material for signage and more.

In cooperation with the print media manufacturer com2C the sustainable panels can now be labeled and illustrated in an equally environmentally friendly way.

Jeroen Drabbe: BioPanel is an environmentally friendly, plant-based panel material made from industrial hemp fibers and biopolymers that is available in different thicknesses. It is primarily used for all kinds of signage and can be both recycled and composted. This makes BioPanel completely recyclable and CO₂-neutral.

Jeroen Drabbe: In the beginning there was the company Abelleisure, which has been working on the conception of leisure routes for more than 15 years. In addition to the route, the signage is also crucial for the success of a leisure route. It quickly became clear that a hiking or cycling route through exceptionally beautiful nature could not be marked very well with conventional signage. Because in most cases this is made of aluminum or HPL and comes with a huge CO₂ footprint.

Because no environmentally friendly and CO₂-neutral material was available on the market for signposting the natural routes, we quickly started to develop one ourselves. As an alternative to the aluminum sign, BioPanel was created - a biodegradable panel material that is not only suitable for signs.

Jörgen Walch: After the perfect background for sustainable signposts had already been developed with BioPanel, the sustainable print medium was still missing. Direct printing was not an option due to the poor ecological balance.

This is where we came into play as a print media manufacturer and developed a robust and yet completely PVC-free adhesive film for labeling.

Jörgen Walch: The lettering should of course correspond to the intended use outdoors and must be able to withstand wind and weather. We needed a self-adhesive material that does not shrink and has a high adhesive strength of at least 15N/inch. In addition, a surface that makes a high-quality print image possible. The special challenge here was the adhesive, which of course had to meet the environmental requirements and had to have a very high adhesive strength. Good adhesion must be maintained over the long term, regardless of strong temperature fluctuations and humidity.

GreenFilm 100 PP LUVESS MW ultra tack air adh FR was developed under these specifications. The self-adhesive film is the ideal partner for BioPanel: Green Film is PVC-free and has a permanent adhesive with ultra-strong adhesion. The film also meets the requirements of fire protection class EN 13501.

The protective laminate Protect 70 PP matt FR from com2C provides the necessary UV protection that is required for outdoor use - with a shelf life of up to 5 years.

Jörgen Walch: Most conventional signs are made of aluminum or polymer composite materials. This makes them weatherproof, but unfortunately not sustainable or environmentally friendly. Conventional signs are not biodegradable, not CO₂-neutral and not free of fossil materials. Some recycling is possible, but there is no complete cycle. Many disused signs have to be scrapped.

When you think of the numerous signs on charging stations for electric vehicles, it becomes clear that we urgently need completely green solutions for signage.

Jeroen Drabbe: BioPanel has no negative impact on our environment. We achieve this by processing rapidly renewable plant fibers - here we use industrial hemp grown locally in the Netherlands. We combine these vegetable fibers with biopolymers (PLA), which are produced during sugar production. During production, the fabrics do not have to be heated to a particularly high level, which keeps energy costs within reasonable bounds.

As a result, we get a very stable and resistant panel material that can be used indoors and outdoors and has a durability of at least 10 years. And at the end of its life, it can be recycled or biodegraded. We manage without fossil raw materials and high energy consumption - this makes BioPanel CO₂-neutral. In comparison, the production of 1 kilogram of HPL emits 1.3 kg of CO₂ and the production of 1 kilogram of aluminum emits 9.2 kg of CO₂.

Jeroen Drabbe: In addition to signposts and signs, numerous applications are conceivable. BioPanel is very robust and suitable for outdoor use. Wall panels, furniture, coasters, puzzles, medals and records are currently being made from Biopanel. The environmentally friendly material with hemp fibers can be laser cut and can also be used as granules for the injection molding process. Wherever conventional plastics are currently used, BioPanel can also do the job. And it's sustainable and CO₂-neutral.

Jörgen Walch: We are gradually converting our product range. Currently, 62% of our products already have environmentally friendly properties and bear our "GoGreener" label. In advertising technology, the demands regarding environmental protection are increasing. We are proud to be able to offer more and more green solutions and will do our best to ensure that all our products are green soon.

In addition to our products, we also look for green solutions in packaging and shipping - we ship CO₂-neutral and replace plastics wherever possible.

Jeroen Drabbe: We're not the only ones who want to preserve this world for our children and make it a better place wherever possible. With the use of BioPanel everyone can make a contribution, because our bio panels are uncompromisingly sustainable and fully recyclable.

We are currently noticing that consumers are increasingly dealing intensively with their consumption and the raw materials used. BioPanel offers numerous possible applications for the advertising industry. The BioPanel panels are available in different formats and thicknesses and are suitable for different types of processing: drilling, milling, sawing, laser cutting and also injection molding are possible. The environmentally friendly and recyclable panel material can be used indoors and outdoors. In addition to path markings, information boards and furniture, many other applications are conceivable, for example in the construction industry.

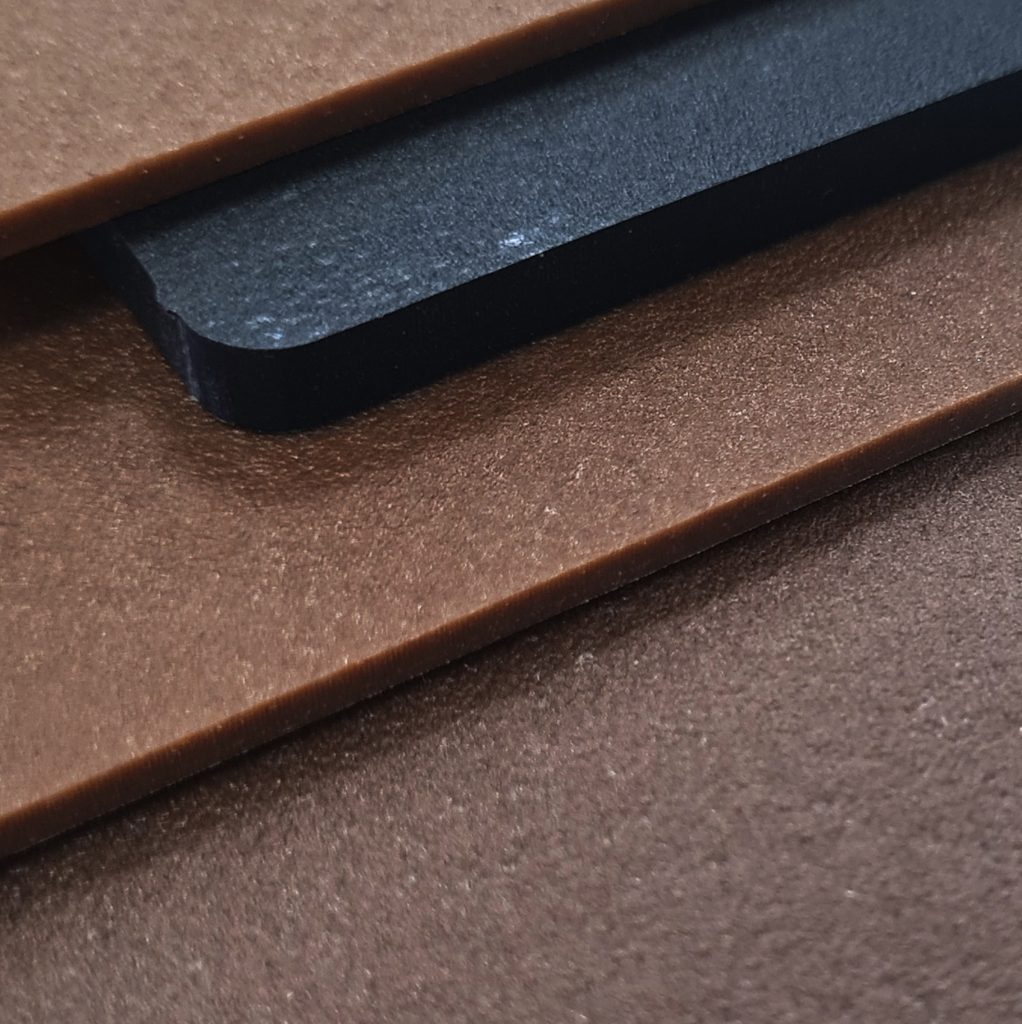

Jeroen Drabbe: We are constantly working on improvements. The color of the biopanels is currently a big topic. The natural color tone, a warm brown, changes under the influence of strong UV light. Even if this does not change the strength and stability, we try to make the visual impression perfect. We are currently testing natural substances such as turmeric to stabilize the colour. Charcoal as a coloring component has already proven itself. We can use it to color Biopanel very nicely black. The elegant matt black look together with excellent ecological properties open up exciting areas of application for the material in the area of displays and POS.

The perfect combination: Biopanel + GreenFilm ultra tack

BioPanel is an innovative product manufactured by BioPanel BV. It is a sustainable alternative to traditional building materials with a multitude of advantages.

- Sustainable materials: BioPanel is made from natural and renewable raw materials such as plant fibers and biodegradable binders. These materials have a low ecological footprint and help reduce dependency on non-renewable resources.

- Circularity: BioPanel is circular to 100%. This means that all components of the panel are recyclable and can be returned to the production cycle after use. This minimizes the amount of waste and maximizes resource efficiency.

- Biodegradability: The materials used in BioPanel are biodegradable. This means they can naturally degrade over time without leaving any harmful residue or waste behind. This property allows for environmentally friendly disposal and minimizes the impact on the environment.

- Energy-efficient production: The production of BioPanel requires less energy consumption compared to conventional building materials. This contributes to reducing greenhouse gas emissions and conserving natural resources.

- Health and Environmental Considerations: BioPanel contains no harmful chemicals or toxic ingredients. This minimizes potential risks to human health and the environment. It is an environmentally friendly product that contributes to a sustainable and healthy living and working environment.

GreenFilm 100 PP LUVESS MW ultra tack air adh FR is a product manufactured by com2C. It is a film with multiple benefits and uses.

- Sustainable material: GreenFilm 100 PP LUVESS MW ultra tack air adh FR consists of 100% polypropylene (PP). PP is a recyclable plastic and has a low ecological footprint compared to other plastics. By using PP, GreenFilm contributes to reducing the consumption of non-renewable resources.

- High Adhesion: GreenFilm 100 PP LUVESS MW ultra tack air adh FR features Ultra-Tack adhesive technology that ensures strong adhesion to various surfaces. This allows the film to be safely and effectively applied to different materials.

- Air permeability: GreenFilm 100 PP LUVESS MW ultra tack air adh FR has air adhesion technology that allows air permeability. This allows air bubbles to escape from under the film as it is applied, resulting in a smooth and bubble-free finish.

- Versatile applications: GreenFilm 100 PP LUVESS MW ultra tack air adh FR can be used in various areas, such as in the packaging industry, for displays, advertising materials and much more. It is suitable for both indoor and outdoor use.

- Environmentally friendly: By using GreenFilm 100 PP LUVESS MW ultra tack air adh FR, companies can achieve their sustainability goals and act more environmentally conscious. The use of recyclable PP and the reusability of the film help reduce waste and protect the environment.

The perfect circle

What does 100% circular mean?

Sustainable materials: BioPanel consists of natural raw materials such as plant fibers and biodegradable binding agents. These materials are renewable and have a low ecological footprint compared to traditional building materials.

Biodegradability: The materials used in BioPanel are biodegradable, which means they can naturally degrade over time. This avoids creating harmful waste that ends up in landfills or pollutes the environment.

Fully Recyclable: All components of the BioPanel can be recycled. This means that after their use they can be fed back into the production cycle to make new panels or other products. Recycling reduces the need to reclaim raw materials, thereby reducing resource consumption.

Low energy consumption: Less energy is required to manufacture BioPanel compared to conventional building materials. This helps to reduce greenhouse gas emissions and the ecological footprint.

No Harmful Ingredients: BioPanel contains no harmful chemicals or toxic ingredients. This prevents harmful substances from being released into the environment when the product is disposed of.

The combination of all these properties makes BioPanel circular to 100%. It helps reduce the environmental impact of building materials by providing a sustainable and eco-friendly alternative.